Traditional manufacturing vs. 3D printing shows a clear contrast in the manufacturing industry, with each having different advantages and disadvantages. While 3D printing, sometimes referred to as additive manufacturing, is growing as a force that is transforming the way we produce items, traditional manufacturing processes have been used for decades as the foundation of industrial production. This article will explore the differences between 3D printing and traditional manufacturing by studying applications, procedures, and potential effects on the manufacturing industry.

Traditional Manufacturing

Casting, cutting, molding, and shaping are only a few of the well-known processes that are involved in traditional manufacturing. These techniques usually require removal operations, in which extra material is taken from raw materials to mold them into desired shape. This is considered a subtractive process. Typical traditional production methods include casting for complex designs, CNC machining for metal components, and injection molding for plastic parts.

Benefits of Traditional Manufacturing:

- A variety of materials are available, like composite materials, metals, plastics, and ceramics.

- Infrastructure and supply chains are set up for mass production.

Limitations of Traditional Manufacturing:

- Longer wait times for setup and tooling.

- Limited design freedom, especially for complex shapes.

- Increased expenses related to labor, waste materials, and equipment.

- Less environmentally friendly because of energy use and wasted materials.

3D Printing

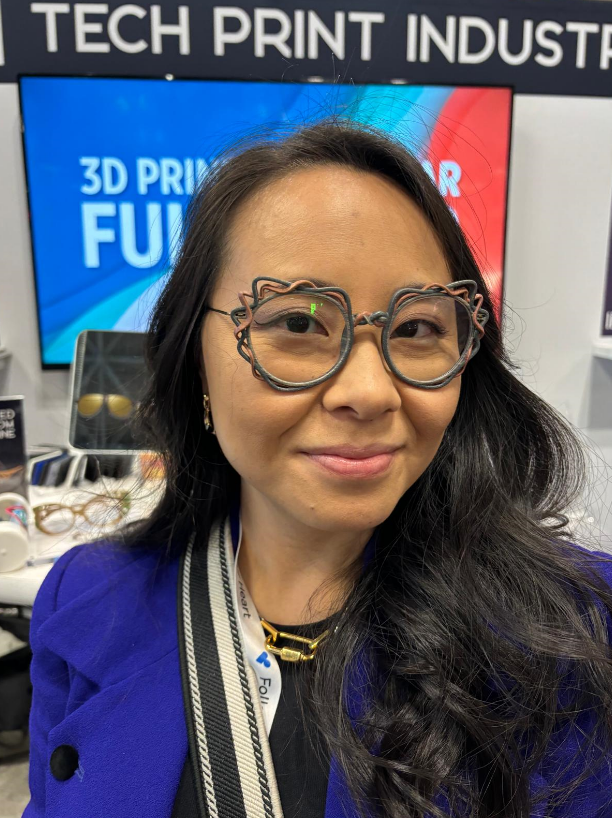

3D printing is a manufacturing technology that has the potential to revolutionize various industries. It manufactures products from digital drawings, layer by layer. Because 3D printing is additive rather than subtractive, material is added exactly where it is needed, which reduces waste and allows for complicated shapes. Because of its adaptability, it is extensively utilized in a variety of industries, including aerospace and medical as well as customized manufacturing and prototyping.

The Benefits of 3D Printing

- Time to market is shortened via design cycles and rapid prototyping.

- More creative freedom, enabling complex and flexible geometries.

- Production is done on demand, eliminating the requirement for pricey inventories and tools.

- Less energy and material waste, resulting in a more environmentally friendly production process.

The Limitations of 3D Printing

- Limited choice of materials in contrast to conventional manufacturing (at this time).

- Higher overall material and equipment investment costs.

The Future of Traditional vs. Additive Manufacturing

The differences between 3D printing and traditional production are blurring as additive manufacturing technologies develop. Mixed methods, which combine additive and subtractive processes to optimize design flexibility and manufacturing efficiency, are becoming more and more popular. Furthermore, 3D printing is becoming stronger thanks to developments in materials science, which make it possible to create functioning end parts that were previously unimaginable.

In conclusion, a wide range of factors, such as project needs, budget limits, and production targets, influence the decision between traditional manufacturing and 3D printing. 3D printing offers unmatched design freedom and agility, while older methods offer scalability and reliability, but no innovation. There can be reasons for both in the future. Just like we have denim jeans and yoga pants, they are different and can coexist. In a market environment that is constantly changing, manufacturers can use the right blend of these technologies to stay innovative and competitive, by optimizing the advantages of each method.